Thermal oxidiser for endothermic engines and off-gas

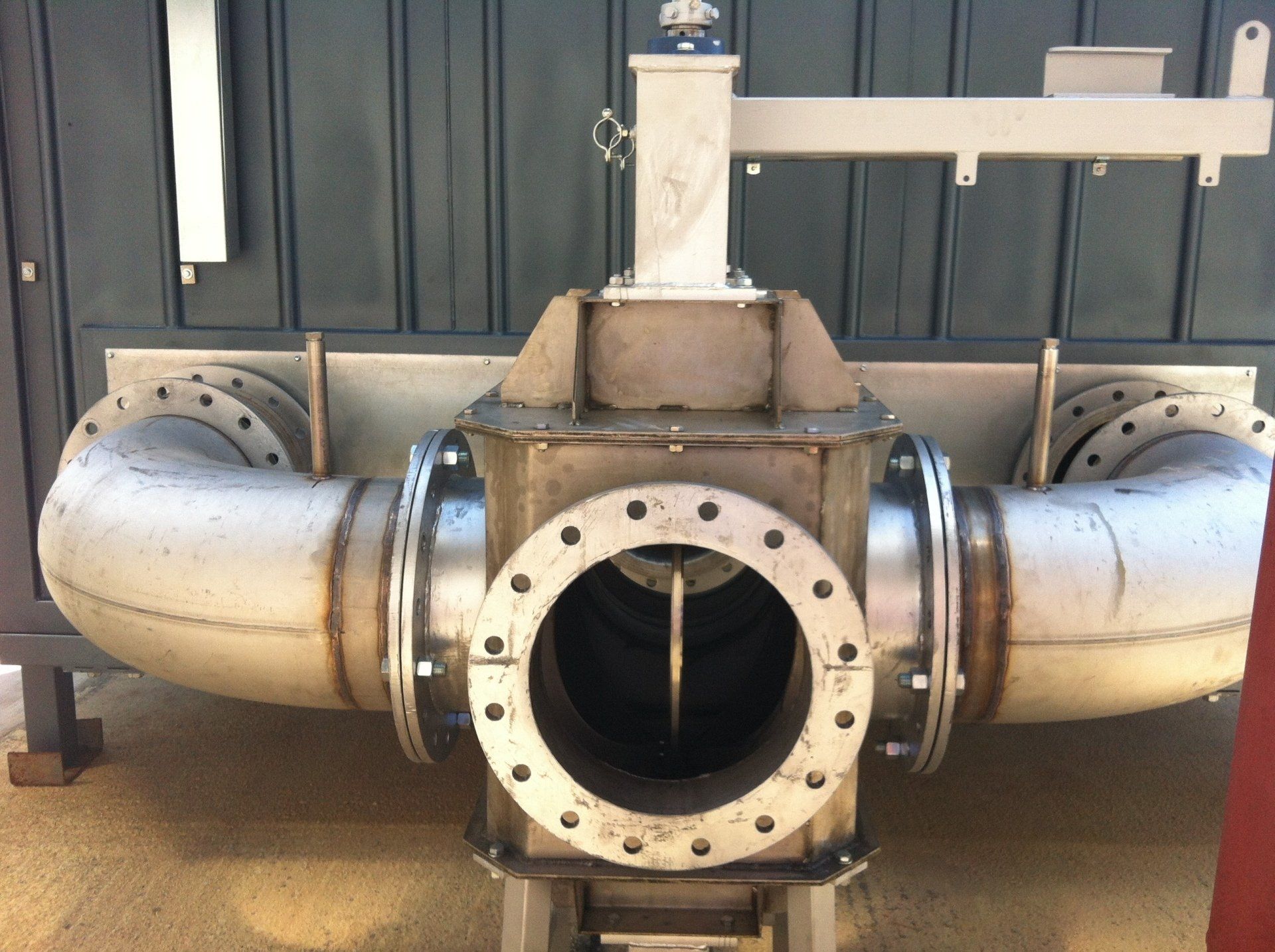

LAI has designed and developed an afterburner for endothermic engines (Regenerative Thermal Oxidizer RTO).

This postcombustor, thanks to high-temperature thermal oxidation, is capable of converting organic residues and carbon monoxide present in the exhaust gases of endothermic engines into carbon dioxide and water vapour.

How the afterburner work

Thanks to a heating system with electric resistances, and to the hot fumes from the exhaust gases, in two or three hours the LAI thermal engine afterburner reaches operating temperature. From here, with a thermal recovery system, exchanging the hot flows in the two tanks filled with ceramic material, a self-sustaining condition is created, also thanks to a small input of biogas.

The final stages of the system

The endothermic engine afterburner manufactured by our company is fully controlled by a PLC and requires little to no intervention from the operator.

The management system, remotely controllable, allows for immediate intervention, thus avoiding engine downtime due to insufficient pollutant reduction.